An Unbiased View of China Injection Molding

Wiki Article

All About China Injection Molding

Table of ContentsGetting My China Injection Molding To WorkThings about China Injection MoldingThe Definitive Guide to China Injection MoldingChina Injection Molding for Beginners

What is injection molding? Injection molding is a complicated production procedure. Utilizing a specialized hydraulic or electrical device, the procedure melts, infuses and establishes plastic into the form of a metal mold that's suited the device. Plastic shot molding is one of the most extensively utilized parts manufacturing procedure for a variety of reasons, including:: suppliers can select the mold and mildew design and type of thermoplastic that's used for every part.: as soon as the process has been set up and also tested, injection molding makers can create hundreds of things per hr. Making use of electrical injection molding machines Makes the procedure relatively power efficient.: if the procedure criteria are tightly controlled, the shot molding procedure can generate thousands of components swiftly at a regular top quality.

: whether producers are trying to find solid, tensile or extremely in-depth components, the injection molding procedure has the ability to create them at a top quality continuously. This cost-effectiveness, performance and element quality are simply several of the factors why lots of markets choose to utilize injection molded parts for their products.

Not known Factual Statements About China Injection Molding

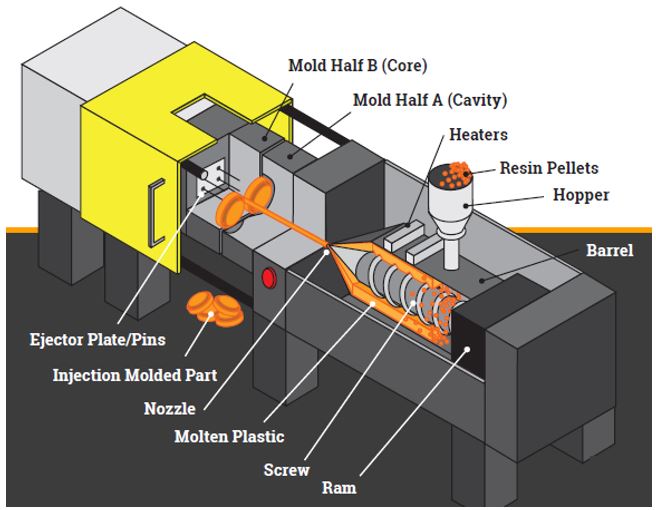

Each mold and mildew device is made up of 2 components: the cavity as well as the core. The dental caries is a set part that the plastic is injected into, and the core is a relocating component that fits right into the cavity to help create the part's final shape. Depending upon needs, mold devices can be made to create numerous or complicated elements.As a result of the high level of design as well as quality of products included, developing mold and mildew devices is a long as well as pricey process. For this reason, before creating a last bespoke mold, it's recommended that devices are created, prototyped and also examined utilizing computer aided layout (CAD) and also 3D printing modern technology (China injection molding). These tools can be made use of to electronically create or produce a model mold that can then be tested in the equipment with the chosen polycarbonate.

Once the best polycarbonate as well as mold and mildew have actually been tested as well as picked, the shot molding procedure can start. Injection molding makers can be powered by either hydraulics or power. China injection molding. Increasingly, Essentra Elements is replacing its hydraulic machines with electric-powered injection molding equipments, revealing substantial expense as well as power cost savings. At their a lot of basic degree, these machines include a feeder or 'hopper' on top of the machine; a long, cylindrical warmed barrel, which a large injection screw beings in; an entrance, which rests at the end of the barrel; as well as the selected mold and mildew tool, which eviction is linked to.

As the screw turns, these pellets are fed progressively into the barrel of the device. The turning of the screw and the warmth read what he said from the barrel progressively warm as well as melt the polycarbonate up until it is molten. Preserving the right temperature levels within this part of the process is vital to ensuring the plastic can be infused efficiently and the last part created properly.

What Does China Injection Molding Mean?

This draws via a set quantity of plastic and also accumulates the stress in the screw prepared for shot. At the exact same time, the two parts of the mold and mildew tool close with each other and are held under high pressure, called clamp pressure. Shot stress and also clamp pressure must be balanced to ensure the part creates properly and also that no plastic escapes the device throughout injection.

This is called 'cooling time', it can likewise vary from a few secs to some minutes browse around this site and also makes sure that the component sets properly before being expelled and ended up on the production line. After the holding and also cooling times have actually passed and also the part is mainly created, pins or plates expel the parts from the device.

In many cases, ending up processes such as sprucing up, dying or getting rid of excess plastic (called stimulates) might be required, which can be finished by various other machinery or operators. Once these processes are full, the components will certainly be all set to be packed up and also dispersed to producers. Exactly how Essentra Components makes use of injection molding At Essentra Components, shot molding is a crucial manufacturing procedure.

The Facts About China Injection Molding Revealed

What is Shot Molding? Injection Molding is a manufacturing procedure for generating parts in big quantity. It is most usually used in mass-production procedures where the same part is being produced thousands or perhaps countless times in sequence. Why You May Wish To Utilize Injection Molding The primary benefit of injection molding is the capacity to range manufacturing en masse.

The rate additionally tends to go down considerably as more components are created. Other advantages consist of the following: Reduced Scrap Rates with Injection Molding Shot molding creates reduced scrap rates family member to standard manufacturing procedures like CNC machining which i thought about this reduced away substantial portions of an initial plastic block or sheet. This however can be a negative family member to additive manufacturing processes like 3D printing that have also lower scrap prices.

Report this wiki page